Back around 1989, I received a request to fix an infusion pump, a device that allows medical staff to pump very small and precise amounts of fluids and medicines into patients.

I was told it would turn on, but

wouldn't start pumping. The display showed rubbish, and pushing buttons didn't

produce any response.

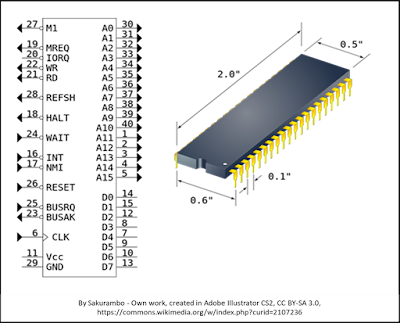

I opened the thing and quickly

discovered a Z80 microprocessor, a computer chip that I had been studying for

some time with the intent of building my own computer. I was very familiar

with it.

From the description of the

problem, it seemed as if the unit was not starting up properly. Opening the unit

and checking pin 26 (the RESET pin), I found...nothing, the pin was floating

(unconnected to anything).

The chip needs the RESET pin to

be held at 0 volts for about a split-second after power-on to start the program

at the beginning. If the chip is not reset, the program may start at a random

line, and the unit will likely hang or run erroneously.

A resistor, diode, and capacitor

usually sufficed to do the job of resetting the chip, but in this case, there

was nothing. I told the owner that I needed to buy the parts and would return

the next day.

At home, I checked the Z80 user

manual. While it explained what the reset pin was for and how to use it, the

manual didn't say it could be left unconnected. Unfortunately, it also didn't say

that a reset circuit was required. Anyway, I already had a course of action, and

I'd know after I put in the parts whether the unit would function or not.

The next day, I brought the

parts, a soldering iron, and some soldering lead to the client's office and soldered the parts in. There was no provision on the board for them, but there was sufficient space for me to place them without difficulty. Once finished, I crossed my

fingers and turned on the power.

Yes! The infusion pump's display

gave an initial display and waited for input. Someone set it up, inputted some parameters, and pressed Start. It worked! A few more tests, and we declared

the unit fit for use.

While basking in the thrill of a

successful repair, I was concerned about the seeming design flaw in a commercial

medical product. I told the client that they should inform the manufacturer

about what we had found so they can recall the units already sold and have them

updated. I went home fully expecting to soon receive a call from some engineer

wanting more details. Unfortunately, there was none. They had either understood

what the problem was and implemented the fix, or they had discovered the issue themselves

and were already putting out a recall order.

Anyway, this was just one of

those repair jobs that sticks in my memory due to its unusual nature.

No comments:

Post a Comment